Home/All Machines/NEW MACHINES/HYDRAULIC PRESSES

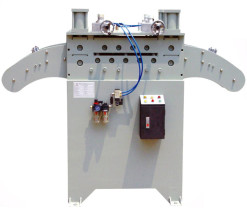

Servo Cold Extrusion Hydraulic Press Machine

Frame Rail Hydraulic Press

Servo Cold Extrusion Hydraulic Press Machine

Product Advantage

1. Use servo control system to save energy 50-70%.

2. Pressure stability,pressure error ±1bar,repeatable positioning accuracy up to±0.02mm.

3. Low failure rate,automatic alarm and fault indication,one-button reset function.

4. Remote maintenance service can be realized.

5. Can set up multi-stage pressure, multi-speed and contiouns fixed-pressure function.

6. Adopting an integral frame structure, high strength, low distortion and durability.

Product Application

The hydraulic press was mainly applied in to metal materials, cold forging, warm forging and extrusion molding, and punching mark, light stretching, cut edges and other materials. Such as cars, motorcycles, bicycles, cell phone case, LED radiator and heat sink, watchcase, hardware tools.

Technical Parameters

| Model | Units | Specifications | ||||||||||

| DKHS-100 | DKHS-200 | DKHS-300 | DKHS-400 | DKHS-500 | DKHS-650 | DKHS-800 | DKHS-1000 | DKHS-1200 | DKHS-1500 | |||

| master cylinder | rated capacity |

ton | 100 | 200 | 300 | 400 | 500 | 650 | 800 | 1000 | 1200 | 1500 |

| stroke | mm | 300 | 400 | 400 | 400 | 500 | 500 | 500 | 500 | 500 | 400 | |

| fast dowm speed |

mm/s | 180 | 160 | 160 | 230 | 230 | 170 | 190 | 210 | 190 | 220 | |

| coining speed |

mm/s | 7-15 | 8-17 | 5-12 | 7-18 | 8-16 | 5-12 | 5-12 | 8-16 | 6-15 | 3-13 | |

| return speed |

mm/s | 170 | 150 | 130 | 210 | 200 | 170 | 180 | 210 | 160 | 210 | |

| system pressure | bar | 240 | 235 | 240 | 240 | 250 | 248 | 240 | 240 | 250 | 240 | |

| knock-out cyinder | ejecting force |

ton | 15 | 30 | 30 | 40 | 40 | 50 | 50 | 60 | 80 | 100 |

| stroke | mm | 200 | 200 | 200 | 200 | 250 | 250 | 250 | 250 | 250 | 200 | |

| mandrel diameter |

mm | 40 | 50 | 50 | 60 | 60 | 80 | 80 | 80 | 80 | 100 | |

| open heigh(slide to bolster) | mm | 600 | 700 | 700 | 700 | 800 | 900 | 1000 | 1100 | 1200 | 1050 | |

| working table size |

L-R | mm | 500 | 700 | 700 | 800 | 800 | 1000 | 1000 | 1200 | 1300 | 1400 |

| F-B | mm | 500 | 700 | 700 | 800 | 800 | 1000 | 1100 | 1200 | 1300 | 1400 | |

| main motor power | KW | 8.6 | 16 | 23.6 | 34.6 | 34.6 | 37 | 60 | 74 | 90 | 110 | |

| over all dimension |

L-R | mm | 1250 | 1680 | 1680 | 2600 | 2650 | 2940 | 3000 | 3660 | 3800 | 4150 |

| F-B | mm | 1430 | 1780 | 1780 | 2100 | 2100 | 2100 | 2300 | 2450 | 2500 | 2680 | |

| H | mm | 2850 | 3480 | 3500 | 3700 | 4050 | 4100 | 4320 | 4560 | 4720 | 4820 | |

Technical Parameters